SGQXNM上牵引旋转膜泡内冷多层共挤吹塑薄膜生产线

SGQXNM up-traction rotation IBC multi-layer co-extrude film-puffing assembly line

产品型号 Product pattern

三层共挤: Three layers co-extrude

SGQXNM 2200×3

SGQXNM 1800×3

SGQXNM 1600×3

SGQXNM 1400×3

二层共挤: SGQXNM 2200×2

SGQXNM 1800×2

SGQXNM 1600×2

SGQXNM 1400×2

一、主要用途:

本生产线运用LDPE、LLDPE、HDPE、MLLDPE、EVA、EAA等塑料原料,生产复合膜基材、液体膜、收缩膜、保护膜、电缆膜、高分子粘接膜及其它多功能工业包装膜等,该制品精度高,可满足高速彩印、复合、涂覆等工艺要求。

二、主要性能特点:

1. 模具采用计算机优化程度设计流道,适应多种原料共挤复合。

2. 高精度的模具和高效率风环冷却系统,保证薄膜厚度均匀,产量高。

3. IBC膜泡内冷系统:膜泡内的冷热气体的更换是运用折径控制系统调整进出风机的风量来控制的。这样,不仅使膜泡折径偏差小,而且制品的透明度高,力学性能也好。

4. 牵引机水平往复式旋转取代模头旋转,大大简化了模头结构,避免了因模头旋转而引起的模头漏料、密封难、维护难等问题。与EPS气液纠偏装置配合使用,克服了膜卷大小头、松紧边等问题,促进收卷膜质量大大提高。

三、主要技术参数:

1. 挤出机: SJ45/30、SJ50/30、SJ60/30、SJ75/30四种机型(可根据用户需要来配置)

整机产量:160~200kg/h

2. 三层(二层)共挤模具和风环

● 模具规格:∮250、∮300、∮350 、∮400、∮450、∮500

● 冷却风环:双风道托膜式风环

● 冷却风机:11KW,变频调速

3. IBC膜泡内冷系统:采用超声波传感器探测膜泡大小,将测得的信号由计算机处理后自动调节膜泡内的冷热气体的进出量,目的是保证膜泡内的气压不变,使膜泡大小保持不变。

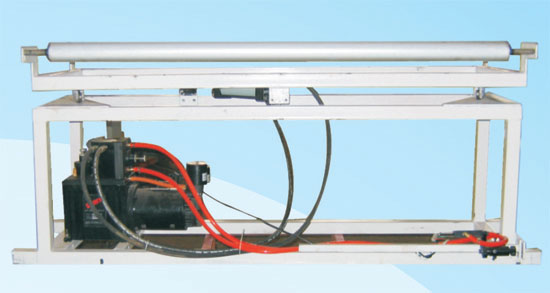

4. 水平旋转式牵引和收卷

● 牵引机为三层塔架式结构,水平摆动,往复旋转360°。

● 旋转速度:10~20分/转,速度可调。

● 上牵引:交流电机变频控制。

● 下牵引:磁粉离合器张力控制。

● 收卷机:双工位被动磨擦收卷。

● EPS气液纠编系统:自动修正跑边、精准快捷。

● 牵引、收卷速度:5-60米/分。

四、 电气控制中心:中心控制台

五、整机外形尺寸:(长X宽X高);9800X6500X9300mm

以上配置可根据用户要求调整,技术参数如有变更恕不另行通知.

|

Ⅰ.Main usage

The line use the materials as LDPE、LLDPE、HDPE、MLLDPE、EVA、EAA etc, product manufacture composite film basic material,liquid film,contractive film,protective film,cable film,macromolecule adhesive film,multifunctional industrial film products.can better operational requirements of high accuracy and high speed color printing, composite and painting products.

Ⅱ.Features of the Machine Set

1.Total crowded the mold head flow a calculator excellent turn the design,adapt various raw materials to push the compound totally.

2. High accuracy film dies and air ring cooling system ensures good film even hickness and high output efficiency.

3. The IBCinternal bubble cooling system use the high precision fold diameter control system adjustting the air current by fan speed adjustment.Have low deviation,the film diaphaneity and mechanics function is improvement.

4. The tractor adopts horizontal swing rotation replaces die rotation and simplifies die structure.It solves problems of leakage,poor sealing and maintenance,etc.Ar-ising from die rotation. It and EPS rectifying system take concerted use,overcome a size of film head,loose tight side etc.problem,promote accept a film quantity to raise consumedly.

Ⅲ.Main techno-parameter

1. Extruding machine: SJ45/30、SJ50/30、SJ60/30、SJ75/30 four pattern(could collocate according to specific needs)

Maximum output for the line:160-200kg/h

2. Three(two)-layer extruding die and the windloop

● Specifications of the die: ∮250、∮300、∮350 、∮400、∮450、∮500

● Cooling windloop:double wind channel sustaining windloop

● Cooling blower:11KW frequency control

3. The IBC system adopts foregn advanced technolohy : the signal measured byultrasonic sensors and then disposed by computer, adjust the air current by control. The speed of the fan which exchange cool and hot air in the bubble, so ensure the size of The Bubble.

4. Haul-off and rolling auxiliary machine:

● Haul-off machine is hteree-floor towerstructure, horizontal and oscillating rotation, it can rotate to the left and right within 360 degrees.

● Rotation speed: 10-20r/min (adjustable)

● Haul-off(up): AC frequency conversion

● Haul-off(down): the magnetic powder clutch tension control

● rolling auxiliary machine :double station driven friction winding.

● The EPS spirit lquid rectity is partial to the device: the work stabilizes the enduring ccurate correction.

● Haul-off and wind speed:6-60m/min

Ⅳ.The electricity control: the center control set

Ⅴ.Dimension of the line (Length × Width × Height): 9800X6500X9300mm

Installing above can adjust according to the customer request. If the technique parameter has the alteration, forgiving not to go another circular.

| 反.jpg)

正.jpg)